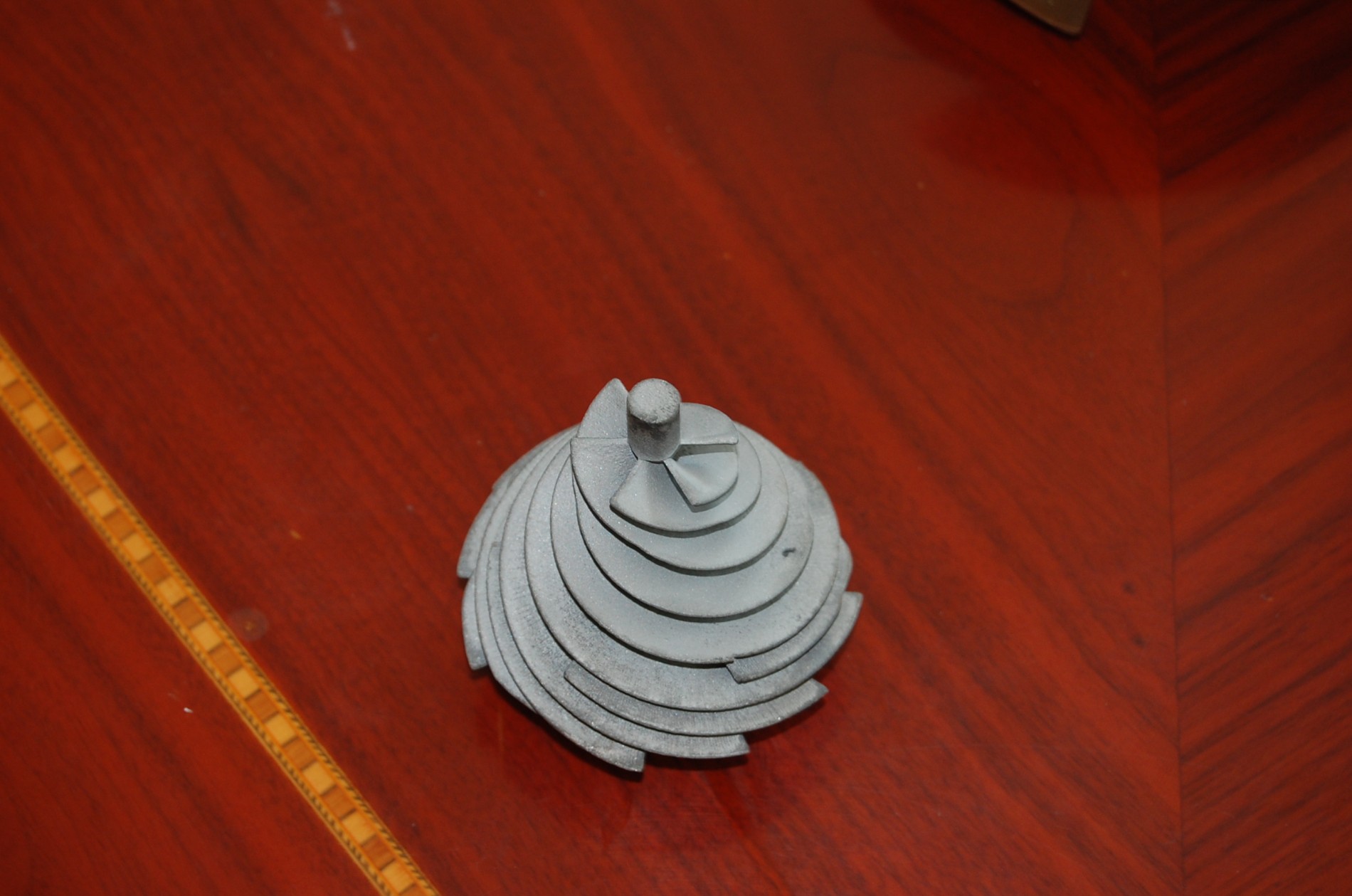

Invsetment castings

The materials used include low alloy steel, stainless steel, aluminum alloy and copper alloy.

Whether it is a stand-alone part or something larger, we believe that good outcomes come from great communication. That is why our commitment is to be a true partner in every project from the initial print to the finished part.

From simple designs to more complex pieces, let us be your trusted cast parts provider.

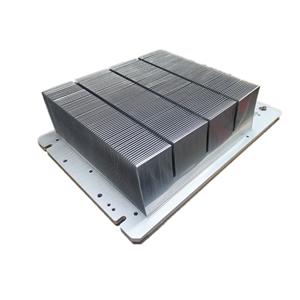

The production process covers investment casting, permanent mold casting, die casting, sand casting, forging, and CNC machining, stamping, progressive stamping. The materials cover stainless steel, carbon steel, brass, aluminum, zinc, gray and ductile iron, etc. For many years our products such as auto accessories, diesel engine parts, shipping accessories, agricultural machinery accessories, machinery accessories and parts have been exported to some Europe countries and USA.

We have a team of professional engineers experienced in the metal manufacturing field in China. We aim to provide our customers the quality products at competitive price with our professional service. Our engineers will evaluate and study every enquiry and design the production process best fit for the enquiry in term of cost and quality. Our inspection team will follow up the process of the production and monitor the quality of the products before shipment.